FAQ

SPLIT SYSTEMS

Units of Competency

Document and apply measures to control WHS risks associated with electrotechnology work

Install and start up single head spilt air conditioning and water heating heat pump systems.

Apply environmentally and sustainable procedures in the energy sector

- Safety glasses

- Cordless drill

- Pliers

- Risk assessments and tool box talks

- Cutting, deburring and flaring pipe

- Bending and brazing copper

- Soldering

- Pressure testing and vacuuming systems out

- Reclaiming refrigerant to a cylinder

- Mounting air conditioning indoor and outdoor units to walls

- Introducing refrigerant from a cylinder to simulate systems with extended pipe runs

- Get up to date with current regulations and standards

- Best practices to follow when installing splits systems

- Learn and understand the additional requirements when installing and decommissioning R32 systems

- Learn about drainage requirements for condensate water and best practices when using condensate pumps

- Care and maintenance of your tools and equipment

- The course is very comprehensive and covers off on all the practical skills you need to install and decommission a split system air conditioner up to 18kW

- Work with a single head split system air conditioners of less than 18kW cooling capacity

- Undertake installation, including running the pipe work of a single head split system air conditioner

- Introduce additional refrigerant when required on extended pipe runs during installation only

- Commission the system after installation is completed

- Undertake removal of refrigerant from the system prior to decommissioning

No. You will complete your online theory from home in your own time. It is self-paced and can be accessed anytime via your phone, iPad or computer device.

Once you have successfully completed all of your online theory, completed all tasks associated with the course and paid in full your certificate will be emailed and posted to you.

QLD:

Can do work up to $3300 without any additional requirements. Work over $3300 requires a licence through QBCC which can only be obtained by a Cert III licence holder.

VIC:

Students in Victoria are required to obtain a VBA Registration/Licence to carry out the work. There are two types of licences students can apply for with the VBA:

- Registration to work under an employer’s licence

- A licence to be a licenced practitioner. A licenced practitioner is able to certify their own work

SA:

Students in South Australia are required to obtain a CBS licence to carry out the work. There are two types of licences you can apply for with the CBS:

- Air Conditioning Installation limited to wall or ground mounted Split Systems

- Air Conditioning Installation (all air conditioning installation)

All plumbers, gas fitters and builders will need to undergo a 30 minute interview regardless of which builders licence is applied for.

Electricians can apply for Air Conditioning Installation limited to wall or ground mounted split systems without an interview, however will only be able to do wall and ground mounted split systems.

Electricians that apply for a builders licence for all air conditioning installations will be required to undertake a 30 minute.

Please note at this point in time all apprentices are not able to obtain a CBS licence until their apprenticeship is complete.

NSW:

Students in NSW are required to hold a Certificate III in Refrigeration or work under someone who holds a Certificate III in order to carry out the work.

The Certificate III is an apprenticeship level qualification and not offered by Get Skilled Training. More information can be found regarding this at the NSW Office of Fair Trading.

Units of Competency

Apply Work Health and Safety regulations, codes and practices in the workplace.

Disconnect – reconnect electrical equipment connected to low voltage (LV) installation wiring.

Locate and rectify faults in low voltage (LV)electrical equipment using set procedures.

Attach cords and plugs to electrical equipment for connection to a single 230 Volt supply.

Attach cords, cables and plugs to electrical equipment for connection to 1000V a.c. or 1500V d.c. supply.

Elective Units

Conduct in-service safety testing of electrical cord connected equipment and cord assemblies (Test and Tag).

Provide cardiopulmonary resuscitation.

Perform rescue from a live LV panel.

Yes, a training permit must be obtained from the Electrical Safety Office before commencing the practical component of this course.

No, you can only undertake electrical work that is outlined on the scope of your licence, which may allow you to disconnect and reconnect cabling from electrical equipment, attached plugs and cords and fault find and replace components within the scope of your trade calling.

No, you can only undertake units of competency that the ESO approves on your training permit. When you enrol and complete the documentation step on your profile, our administration team will set up the units required for your trade background.

Yes, we run refresher courses to ensure you are up to date with safe work practices including isolation procedures, mandatory testing and other safety procedures. Our training team can also provide information regarding relevant Australian standards, risk assessments, tools and equipment that is suitable to undertake this work.

You can complete the course in approximately 6 to 8 weeks, depending on your electrical work permit, training, assessments, and logbook completion. The practical training takes between 2 to 5 days, while the online theory component requires around 6 to 20 hours. Before starting any training, you must obtain an electrical work permit from the Electrical Safety Office, which takes approximately 2 to 3 weeks. Once all course components, including theory, practical training, and logbooks, are completed and all fees are paid, your certification will be issued.

Students should complete this restricted electrical licencing course within 6 months.

Get Skilled Training is dedicated to providing quality training to ensure you get the most out of the course and come away with new skills.

- Our trainers have 20+ years of industry experience within the electrical industry

- Our class sizes are kept small and have a great student to trainer ratio – 1 to 6 for restricted electrical and 1 to 8 for test and tag – so you can the most out of the course.

- Our restricted electrical course is catered so you can enjoy delicious food while you train and enjoy the learning process.

- We only use quality training tools and equipment, so you can undertake work safely and our electrical fault simulators will prepare you for the real world.

- When you complete the course, you leave with the information and skills you need to undertake the job in the field, including safe work procedures, tool and equipment lists.

Once you enrol with Get Skilled Training, you can start the online theory while you wait for your training permit with the ESO to be approved. Our friendly administration team is here to guide you through the application process with the Electrical Safety Office for your permit and your restricted electrical licence.

Units of Competency

The nationally accredited test and tag qualification consists of two competencies:

UEECD0007 – Apply work health and safety regulations, codes and practices in the workplace

UEERL0003 – Conduct in-service safety testing of electrical cord connected equipment and cord assemblies.

Undertaking this course will give you the skills to be a ‘competent’ person when it comes to testing and tagging equipment.

A person who is appointed as ‘competent’ by their employer can test and tag. A competent person is someone who has acquired, through training, qualifications, experience (or a combination of these) the knowledge and skill required to carry out testing and tagging.

Therefore, you do not need an electrical licence to test and tag the electrical equipment within your own workplace. Instead, you can undertake UEERL0003 – Conduct in-service safety testing of electrical cord connected equipment and cord assemblies to gain the necessary training with Get Skilled Training.

However, if you want to conduct test and tag as a business in Queensland, you must apply for a Restricted Electrical Contractor’s licence through the Electrical Safety Office (ESO). This may require extra training in a business unit such as BSBESB402 – Establish legal and risk management requirements of new business ventures.

Yes. An electrician is considered to be a ‘competent’ person for testing and tagging. Electrical workers still may undertake UEERL0003 – Conduct in-service safety testing of electrical cord connected equipment and cord assemblies as a refresher to get up to date with leakage testing methods and current industry requirements in relation to frequency of testing.

A ‘competent’ person can test and tag. A competent person is someone who has acquired, through training, qualifications, experience (or a combination of these) the knowledge and skill required to carry out testing and tagging.

The nationally accredited test and tag qualification consists of two competencies:

UEECD0007 – Apply work health and safety regulations, codes and practices in the workplace

UEERL0003 – Conduct in-service safety testing of electrical cord connected equipment and cord assemblies.

Undertaking this course will give you the skills and knowledge to become a ‘competent’ person to perform testing and tagging. Therefore, you do not need an electrical licence to test and tag the electrical equipment within your own workplace. Instead, you can undertake UEECD0007 and UEERL0003 to gain the necessary training.

However, if you want to conduct test and tag as a business in Queensland, you must apply for a Restricted Electrical Contractor’s licence through the ESO. This may require extra training in a business unit such as BSBESB402.

UEECD0007 and UEERL0003 do not expire.

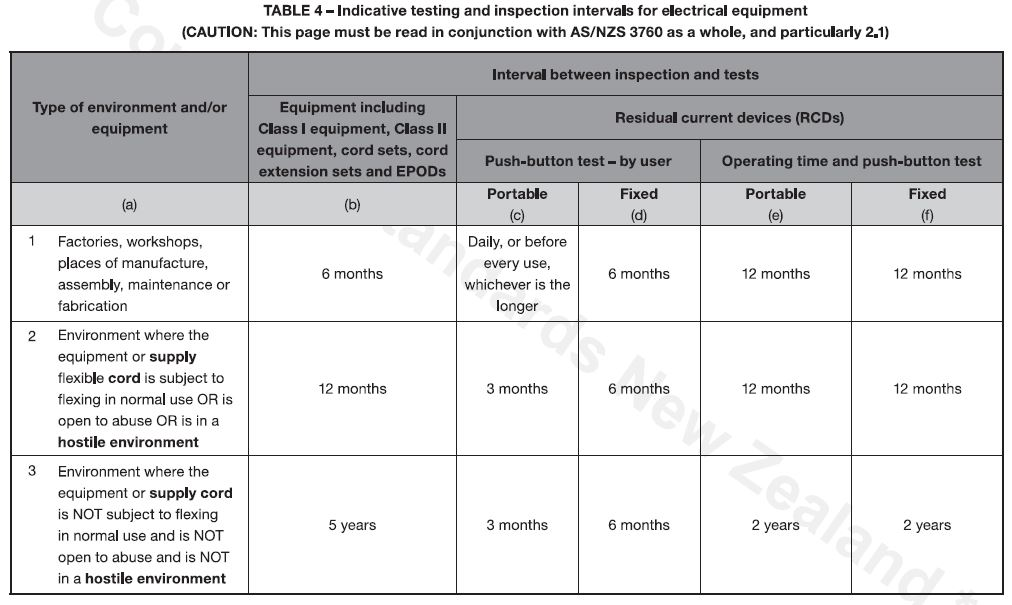

However, it is important that your test and tag skills and knowledge remain current. This includes keeping updated with any changes to the legislation or Australian standards such as AS/NZS 3760.

Completing an online ‘refresher’ test and tag course is one way to maintain currency. Speak to the team at Get Skilled Training to undertake a refresher course today.

On seek test and tag jobs are paying approximately $45,000 to $55,000 p/a.

Yes. You do not need an electrical licence to test and tag the electrical equipment within your own workplace. Instead, you can undertake UEERL0003 – Conduct in-service safety testing of electrical cord connected equipment and cord assemblies to gain the necessary training.

However, if you want to conduct test and tag as a business in Queensland, you must apply for a Restricted Electrical Contractor’s licence through the ESO. This may require extra training in a business unit such as BSBESB402 – Establish legal and risk management requirements of new business ventures.

Tests on portable appliances can be conducted using a multimeter or insulation resistance tester however, these meters don’t take into account any damage to the earth connection or conductor and hence could be considered less effective than other methods of measuring earth resistance.

Often a leakage test is required and neither a multimeter or IR tester is capable of conducting this test.

According to AS/NZS 3760, for equipment that contains single phase motors, or if an insulation test fails due to the presence of internal components such as LEDs, the leakage current test is the preferred option.

If the equipment must be energized to close or operate a switching device in order to test the insulation, then the leakage current test shall be performed.

If you want to do a complete test to verify the electrical safety of a portable appliance, a multimeter does not have the capability to test the leakage current of an appliance, so a PAT should be used.

A portable appliance tester (or PAT) is a machine that is specially designed to test the safety of electrical cord connected equipment and cord assemblies.

The PAT conducts an automatic test sequence and gives a clear pass/fail indication based on the type of equipment.

Different PAT’s have different characteristics, often depending on their price.

All basic PAT’s can conduct:

- class I testing

- class II testing

- extension lead testing.

Leakage testing is also mandatory for some types of equipment. A leakage current test is required for single phase motors and equipment with internal switches.

Some PAT testers can also conduct leakage testing.

Some appliances (class II – also called double insulated appliances) do not require an earth conductor. Double insulated appliances, as the name suggests, have a double layer of insulation.

Class II, or double insulated appliances, are designed to make sure no live wire can touch the outer casing.

Even if a live wire becomes loose, it limits the chance of a person getting an electric shock, because the wire cannot touch the outer casing due to the appliance being insulated.

Double insulated appliances will only have two pins, one for the active conductor and one for the neutral conductor. They will also have a special symbol designating them as double insulated.

Double insulated appliances should not be earthed. If the appliance is earthed, this introduces the possibility of a shock hazard.

Class II equipment may have the following tests conducted on them:

- Visual inspection

- Insulation resistance

- Leakage current

The amount of items that can be PAT tested in one day depends on the location and the access to the equipment. As a general guide, an experienced PAT tester can PAT test up to 200 items in an office environment and up to 100 in an industrial environment. This will be on the higher end if the items to be tested are laid out for the tester. However, if the PAT tester is required to locate the items themselves, the amount of items that can be tested in a day will be much less.

Three phase testing often requires specialised adaptors and equipment.

When testing and tagging a three phase lead, the following tests should be conducted:

- Visual inspection

- Earth continuity

- Insulation resistance

- Leakage current.

Extension leads are class II appliances.

For an extension lead the following tests must be performed:

- A visual inspection

- Earth continuity test

- Insulation resistance test

- Polarity test